The sectoral integrator “Additive Technologies” has been set up within ROSATOM. It will consolidate efforts of the sector enterprises in additive technologies. It was set up within the structure of ROSATOM’s Fuel Company “TVEL”. “RUSATOM – Additive Technologies” (RusAT Ltd.) mergers competences in science and technology of scientific and production companies of ROSATOM in the project that develops the additive productions in Russia. It controls design and 3D-printers production, additive powders, complete sets, software and 3D-printing services. RusAT Ltd. Coordinates work of the pool of enterprises which includes SPA Centrotech LTd. (the company of Fuel Company of ROSATOM based in Novouralsk, Sverdlovsk Region), JSC ChMP (the Fuel Company TVEL’s company based in Glazov, Udmurtia), FSUE RFNC VNIIEF, Ye. I. Zababakhin RFNC VNIITF, FSUE RI NPA Luch, JSC SPA TsNIITMASH and others.

RusAT develops two additive printing technologies: selective laser melting (so-called layer melting) and straight metal overlay where a metal powder is sent to the overlay zone together with laser beam. SPA Centrotech has developed a pilot production facility to produce powders of non-ferrous metals and stainless steel. The productive output of additive powder fractions of 20 to 60 microns will be not less than 55%. The powder production is planned also at JSC ChMP .

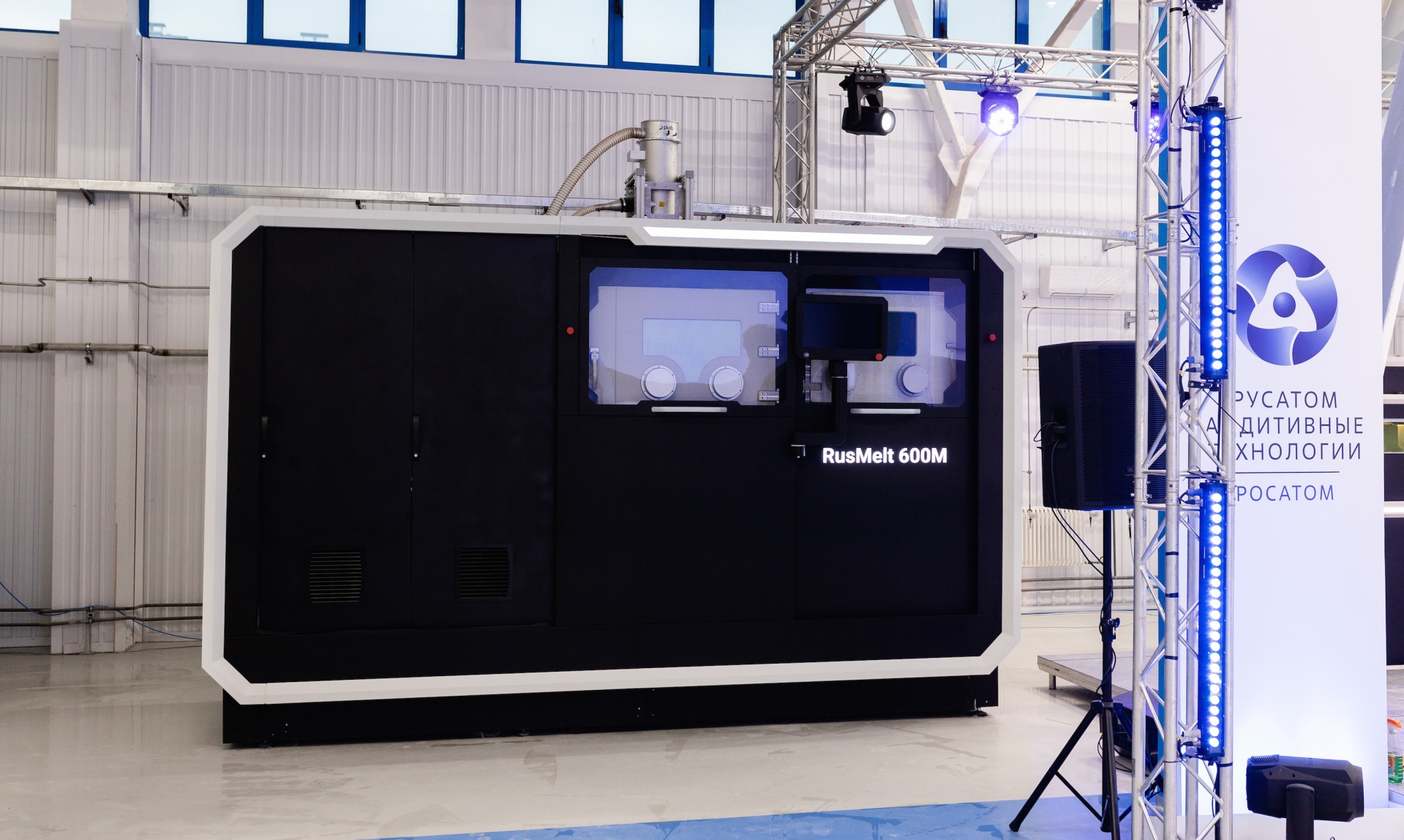

RusAT has developed printers with different plotting scopes. The baseline model is 3D printer with plotting scope size of 300х300х400 mm. Besides, the range includes 3D printers with plotting scope sizes of 600х600х500 mm and 160х160х250 mm. Also, the range includes models using two types of powders for making one item that gives an opportunity to combine materials in production. Depending on the model, one to four lasers can be installed on one 3D printer to increase productivity in printing metal items.

Late 2020, JSC Moscow Composite Metal Plant (an enterprise of Fuel Company of ROSATOM TVEL) opened an Additive Technologies Center (ATC). It is the demonstration science and technology site to test 3D technologies and provide relative services. The Center includes units for printing, post-processing, item research laboratory and testing of specimens. As a result, RusAT Ltd. specialists have an opportunity to verify adopted engineering and technological solutions right after the equipment has been released and promptly correct and improve its design.

The Center has a 3D printer RusMelt-600 made by SPA Centrotech. It operates using the selective laser melting technology with plotting size of 600*600*500 mm to print items with metal powders. Printing metal powder is also produced by SPA Centrotech.

Besides, the Center will be equipped with two more printers made by SPA Centrotech. This equipment meets requirements of international standards. All printers are made all-in-one, equipped with the built-in powder recovery systems and loading and unloading plotting platform capability in a separate chamber without loss of integrity of the working space. They operate using software by RusAT Ltd. specialists. The design of this printer model uses one-of-a-kind powder loading system which excludes idling of the carriage that increases productivity of the equipment.

“Opening of ATC in Moscow is the first step to build whole network of similar centers within the “roadmap” of development of high-technology area “The Technology of New Materials and Substances” until 2024 signed by ROSATOM and the Government of Russia. The next ATC will be set up in 2021 at SPA Centrotech where R&D is planned to test the technology for series-made autocatalysts and hydrogen energy program implementation. We also plan to open additive technology centers in Saint-Petersburg, Novosibirsk, Perm, Tomsk, Kazan, Khanty-Mansiisk and Rostov-on-Don,” Mikhail Turundaev, General Director of RusAT Ltd. noted.

Besides, ROSATOM’s specialists are developing new national standards GOST R for additive technologies. They will be the basis for certification of materials and items for additive production in nuclear and other areas.

More information you can get at the website of RusAT Ltd.